Fuel cells are considered one of the most promising technologies for a sustainable energy future since they offer an efficient and clean way to generate electrical energy. The infrastructure that supports them is also crucial in this process. It includes conveyor technology.

Fuel cells are electrochemical devices that convert chemical energy into electrical energy. Hydrogen is used as a fuel that reacts with oxygen, producing water, electricity, and heat. Fuel cells are highly efficient, versatile, and environmentally friendly. Because they do not generate harmful emissions, they are a promising alternative to conventional internal combustion engines and batteries. They are increasingly viewed as a key technology for a sustainable energy future, and they are used in areas such as transport, energy generation, and portable power supply.

The role of conveyor technology

Conveyor technology is an indispensable component for the efficient production and successful use of fuel cell systems. On the one hand, efficient and reliable conveying technology in their production increases the performance, reliability, and cost-effectiveness of fuel cell technologies. On the other hand, fuel cell applications are therefore gaining wider acceptance and are being used more extensively in various applications.

The different application areas

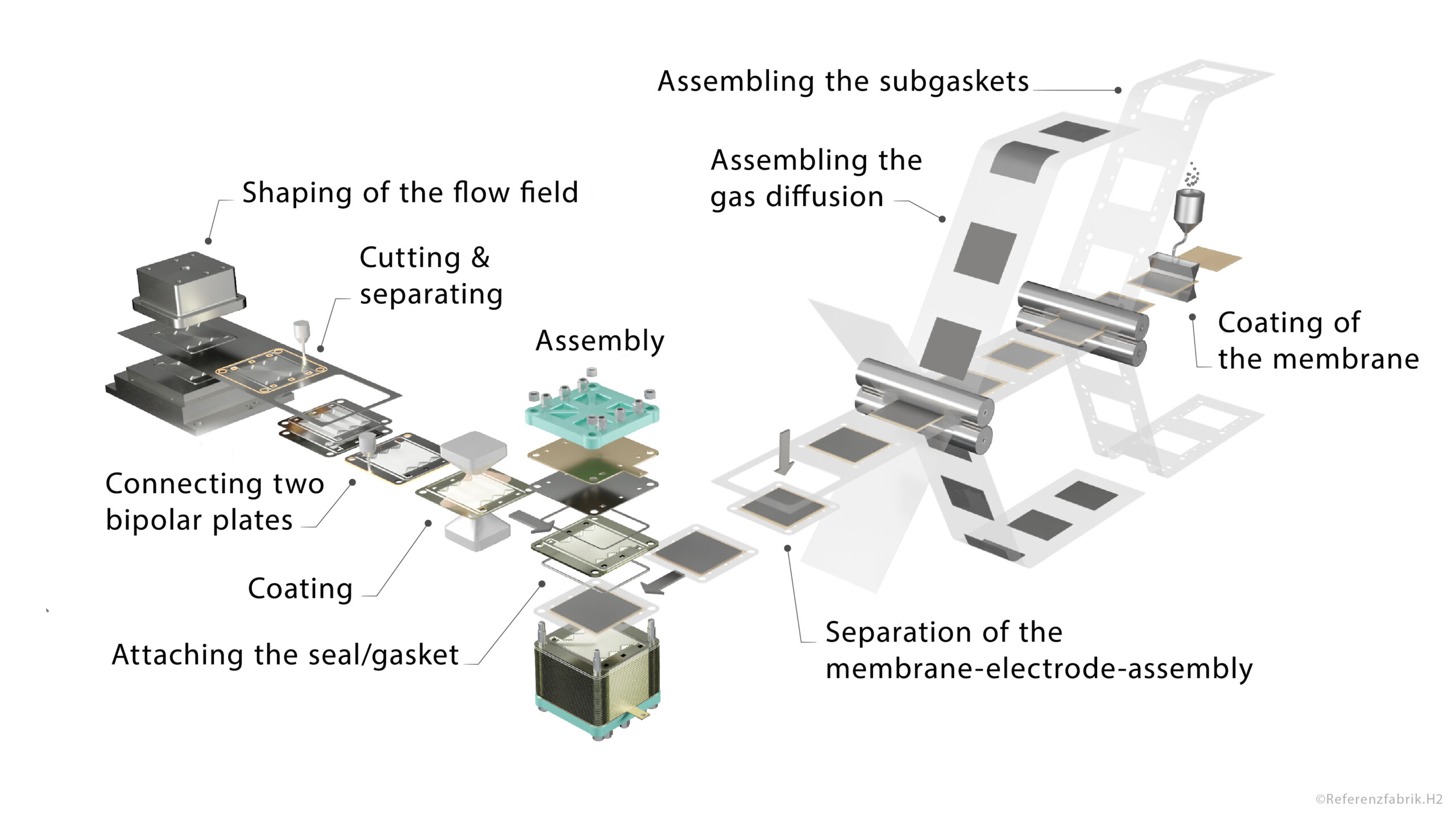

Belt conveyors are used in various phases in fuel cell production processes. Initially, they are used to reliably produce, test, and store the individual materials such as the bipolar plates and membrane electrode unit (MEA). During production, the belt conveyors safely transport the materials through the various stages of the process, for example from cutting and forming to assembly (stacking) of the individual components to form a so-called fuel cell stack. After production is complete, they transport the finished products to packaging and shipping areas. And in the processes of quality inspection and control, the belt conveyors transport the products through the inspection and test stations.

Precautions for the use of belt conveyors for fuel cell production

In order to ensure the safety and efficiency of the processes, certain precautions must be observed when using belt conveyors in fuel cell production. These start when materials are loaded and unloaded onto the belt conveyors. Damage to products or equipment must be avoided in order to guarantee a safe and smooth process. The correct selection and alignment of the belt conveyors, for example with regard to the snap action effect of the individual fuel cell, is crucial to prevent blockages or accumulations that could interfere with the production process or damage the materials themselves. In addition, the speed of the belt conveyors must be adapted to the production process and type of materials transported. In order to detect obstacles or anomalies along the conveyor path, the individual belt conveyors must be correctly aligned with each other and equipped with safety sensors. And to ensure that the belt conveyors are always in optimal operating condition, they must undergo regular preventive maintenance. This includes cleaning, lubrication, and component inspection to detect signs of wear or malfunction.

Requirements for belt conveyors for fuel cells

Belt conveyors used in fuel cell applications require certain characteristics to fulfill the specific requirements of this technology. They must be modular and expandable with vacuum technology. They must also be easy to adjust in various applications and operating conditions. This enables flexible integration into the various production processes for fuel cell systems.

The right solution with the SOLTB belt conveyors

Our SOLTB belt conveyor range offers, among other things, vacuum belts, an innovative solution for conveyor technology in fuel cell technology production. Belt conveyors are designed to transport flat, light, and sensitive products and are therefore ideally suited for fuel cells, but also for battery cells, solar cells, paper/cardboard, and plastic films. Some examples are the vacuum belt conveyor, the unloading belt conveyor, and the centering belt conveyor. All SOLTB conveyors are characterized by their high efficiency and reliability.